Packaged Drinking Water System

3000000.00 INR/Piece

Product Details:

- Source Municipal water supply, Borewell

- Installation Guideline Skilled technician required for setup

- Motor Power 7.5 HP

- Temperature Range Ambient to 60C

- Speed Adjustable

- Efficiency (%) Above 95%

- Automation Grade Automatic

- Click to view more

X

Packaged Drinking Water System Price And Quantity

- 01 Piece

- 3000000.00 INR/Piece

Packaged Drinking Water System Product Specifications

- 3500*1500*2200 mm

- Electric

- Stainless Steel, Food Grade Plastic

- PLC Control System

- Above 95%

- Electric Motor Driven

- Automatic

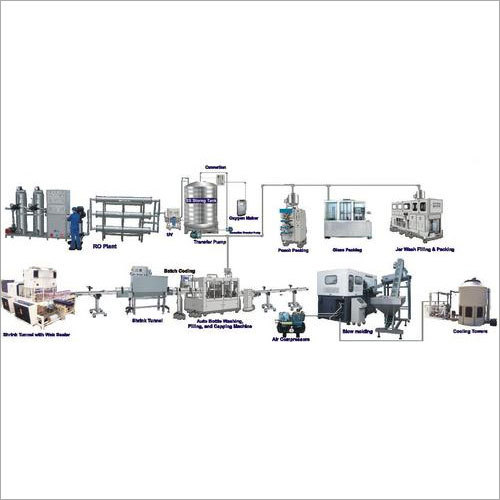

- RO system, UV system, Ozone generator, Filling heads, Capping unit, Conveyor

- Industrial/Commercial Packaged Water Bottling

- PET Bottles

- Ambient to 60C

- 1200 kg

- Adjustable

- Silver (Steel Finish)

- Fully Automatic Bottle Filling Machine

- Polished Stainless Steel

- Yes

- 5.5 kW

- Skilled technician required for setup

- Municipal water supply, Borewell

- Automatic

- Packaged Drinking Water System

- 7.5 HP

Packaged Drinking Water System Trade Information

- West Bengal

Product Description

e have been successfully operating in the industry by offering our utmost quality and superlative Package Drinking Water System. These products are manufactured according to the industry laid parameters and the latest trends. The Package Drinking Water System is featured with an ability to remove all the chemicals and impurities and provide drinking water immediately. To cater to the needs of our valued clients, we manufacture our products in various capacities and specifications within the stipulated time-frame.

The following items are required for a packaged drinking water project :

| SR.N. | ITEM |

| 1 | DLX RO PLANT |

| 2 | RAW WATER PUMP SS 304,GRUNDFOS |

| 3 | SS 304 TANK- |

| 4 | OZONATION |

| 5 | OZONATION TR.PUMP |

| 6 | FINAL WATER TR.PUMP-SS 316- |

| 7 | U.V. |

| 8 | SEMI AUTO BLOW MOLDING MACHINE |

| 9 | BOTTLE WASH.FILL,CAP MACHINE |

| 10 | JAR WASH,FILL,CAP MENUAL MACHINE |

| 11 | JAR WASH,FILL,CAP with conver MACHINE |

| 12 | POUCH PACK MACHINE |

| 13 | ANTISCALE DOSING PUMP |

| 14 | PH DOSING PUMP WITH CREATION |

| 15 | SS 316 ALL PIPE LINE,FITTING TURNKEY SYSTEM |

| 16 | AUTO MULTI PORT VALVE |

| 17 | ISI CHARGE WITH CERTIFICATE |

| 18 | VIBRATING MACHINE CHEKE POUCH |

| 19 | AC 1.5 TON |

| 20 | FREEZ 165 LTR |

| 21 | COMPRESSURE 5 KG FOR BOTTLE FILL |

| 22 | Air dryer |

| 23 | Cooling Tower |

| 24 | LAND |

| 25 | BUILDING |

| 26 | ELECTRICITY DEPOSIT |

| 27 | BORE WELL & RAW WATER TANK |

| 28 | MOLD 2 CAVITY |

Our Target Location :

- West Bengal (Kolkata, Howrah, Darjeeling, Siliguri, Kharagpur, Asansol, Durgapur, Murshidabad, Maldah, Jalpaiguri, Balur Ghat, Baharampur, Medinipur)

- Bihar (Patna, Bhagalpur, Muzaffarpur, Chhapra, Purnia, Siwan, Motihari, Buxar, Samastipur)

- Orissa (Bhubaneshwar, Cuttack, Berhampur, Rourkella, Balasore, Puri)

- Jharkhand (Bokaro, Deoghar, Dhanbad, Jamshedpur, Ranchi)

- Assam (Guwahati, Bongaigaon, Tejpur, Silchar, Kokrajhar)

- Sikkim (Gangtok, Pelling, Gezing)

- Bhutan (Thimphu, Paro)

- Nepal (Katmandu, Combini, Birgunj, Bhaktapur)

- Bangladesh (Dhaka, Chittagong, Khulna, Rajshahi, Sylhet, Barisal, Comilla)

Advanced Automation for Consistent Quality

The Packaged Drinking Water System utilizes a computerized PLC control system to deliver precision in every stage of filling and packaging. Its automatic grade ensures uninterrupted operation, minimal manual intervention, and consistent product quality, safeguarding hygiene standards for industrial and commercial purposes.

Comprehensive Water Purification Process

Equipped with integrated RO and UV systems, as well as an ozone generator, the machine guarantees multi-stage water purification before bottling. This setup removes contaminants, deactivates microorganisms, and ensures the water meets stringent safety norms suitable for packaged drinking applications.

Robust Build and Efficient Operation

Manufactured using stainless steel and food-grade plastic, the system boasts a polished surface and corrosion-resistant design. Operating with a powerful electric motor, it offers adjustable speed and above 95% efficiency, making it ideal for high-volume production while maintaining energy effectiveness.

FAQs of Packaged Drinking Water System:

Q: How is water purified before bottling in this system?

A: The Packaged Drinking Water System processes water through reverse osmosis (RO), UV sterilization, and ozone generation to eliminate impurities, neutralize microorganisms, and ensure the final product is safe for consumption.Q: What is the installation process for the machine?

A: Installing this machine requires a skilled technician due to its complex automated features and integrated accessories. Proper setup ensures optimal performance, safety, and compliance with operational standards.Q: When is the packaged water ready for commercial distribution?

A: Once the water passes through all purification stagesRO, UV, ozoneand the bottles have been filled, capped, and conveyed by the automatic system, the packaged drinking water is immediately suitable for industrial and commercial distribution.Q: Where can this system be used and what are its applications?

A: It is primarily designed for industrial and commercial settings such as bottling plants, water packaging units, and beverage factories where high volumes of packaged drinking water are required.Q: What benefits does the PLC control system provide?

A: The computerized PLC control allows for seamless automation, real-time monitoring, and precise operational control, enhancing consistency, efficiency, and reducing manual labor.Q: How does the adjustable speed feature enhance production efficiency?

A: The systems adjustable speed mechanism enables customization of bottling rates to match operational demands and optimize throughput without sacrificing quality.Q: What types of bottles are suitable for this machine?

A: This fully automatic filling machine is compatible with PET plastic bottles, ensuring wide applicability in packaged drinking water production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

SO-SAFE TECHNOLOGIES & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |